For virtually any ambient temperature, from a company with 60 years experience designing and building heat exchangers

Tanks, pumps, process piping, heat exchangers, controllers, software – everything comes from Hayden, so you only have one vendor to deal with

We deliver skids or containers + heat exchangers — connect, add fluid, add miners, and start mining

Patent pending flow control design keeps miners at the right temperature, up to 110º F without water

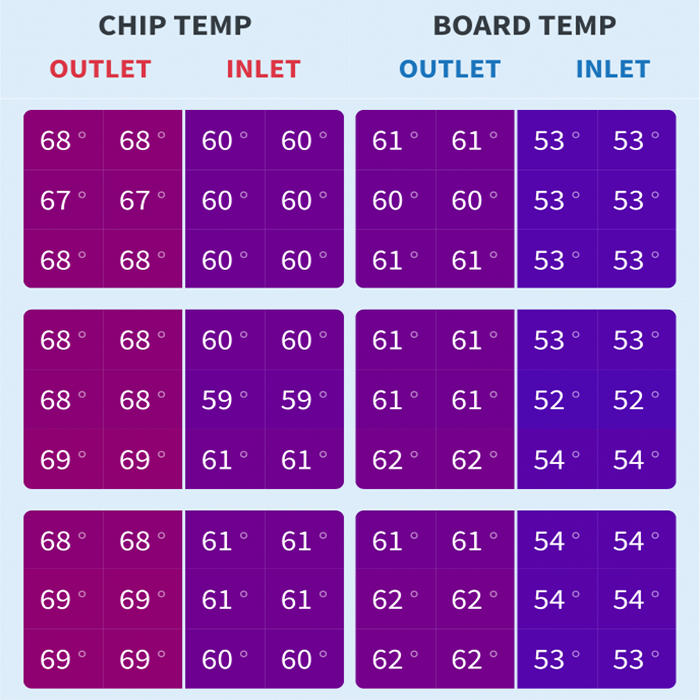

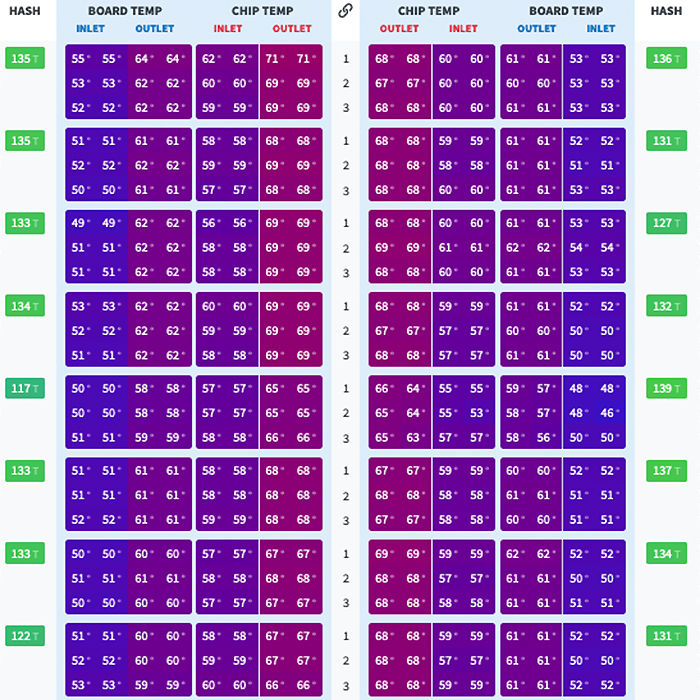

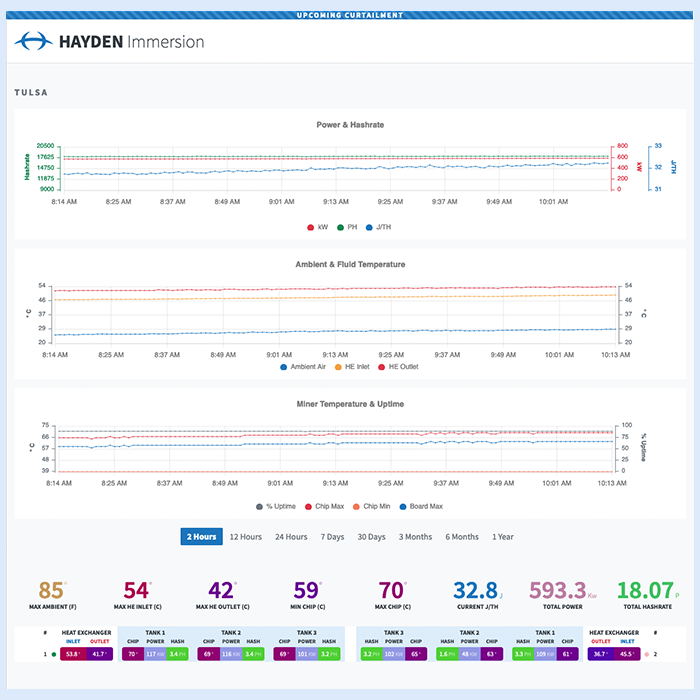

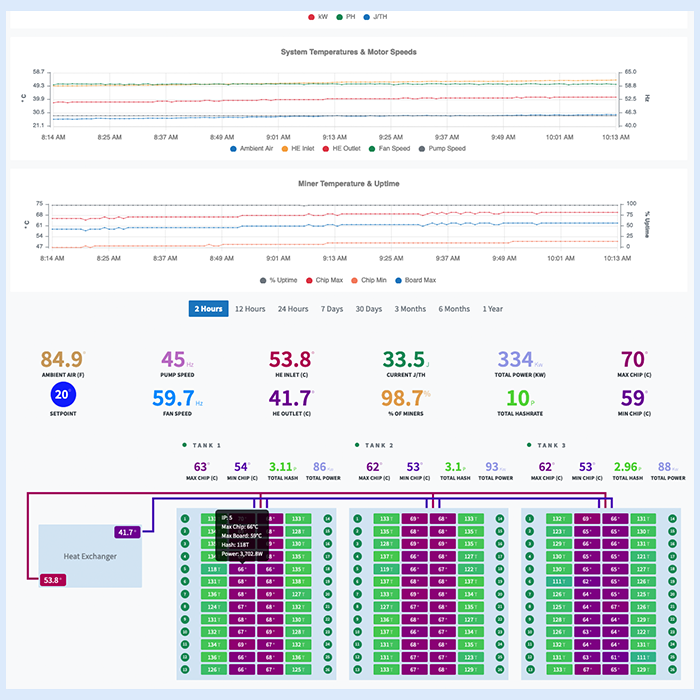

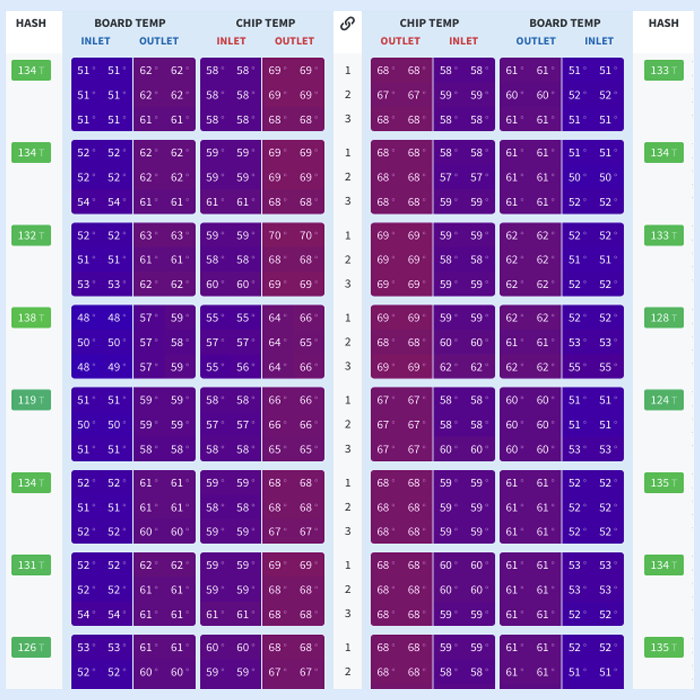

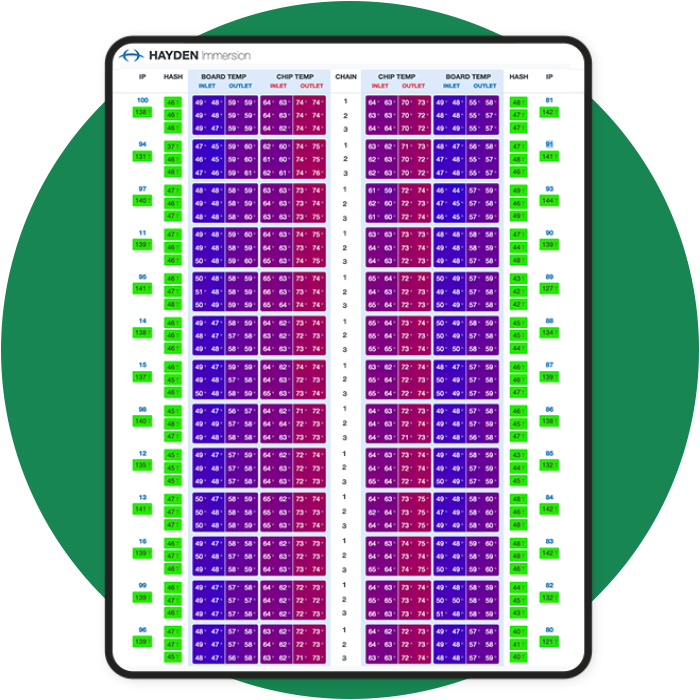

Very little variation of chip temperatures across every miner in every tank

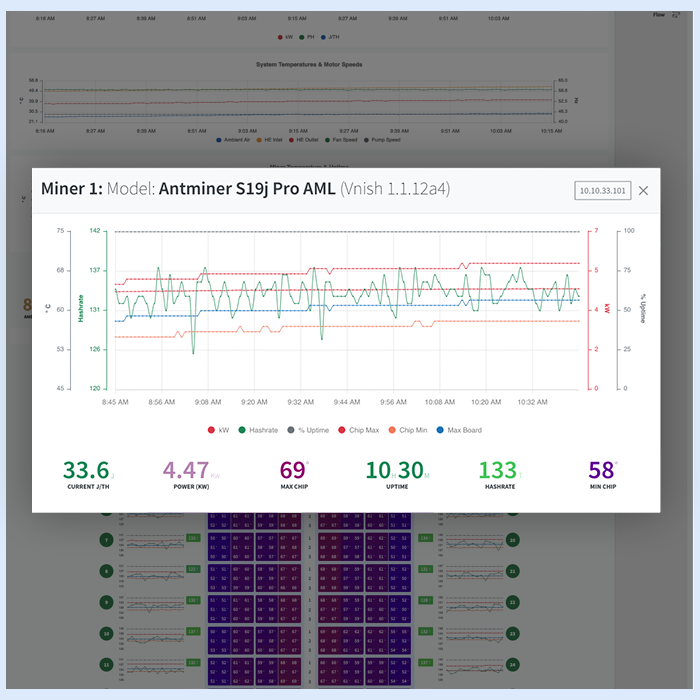

We include a complete O&M software solution for monitoring and managing sites, systems, tanks, and miners

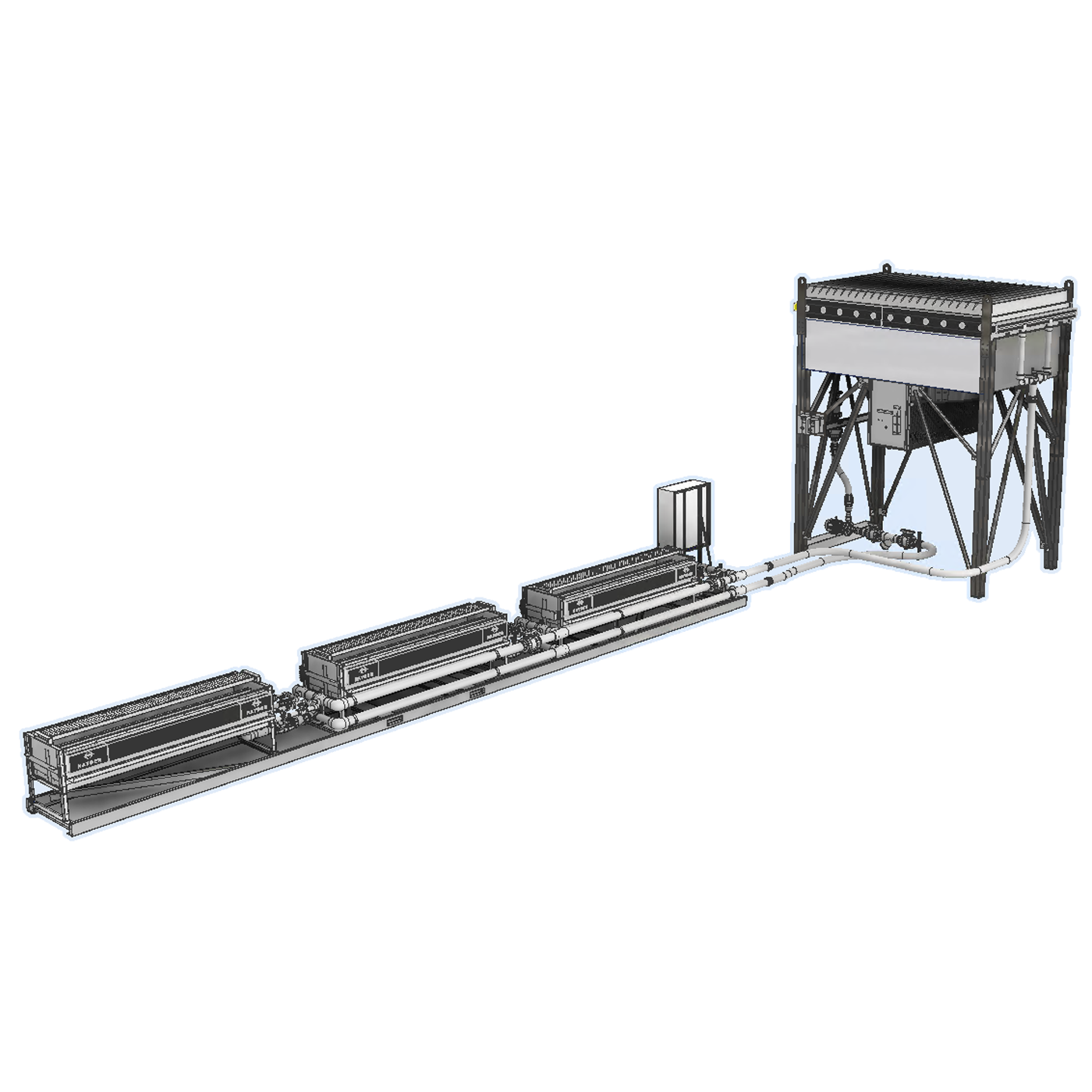

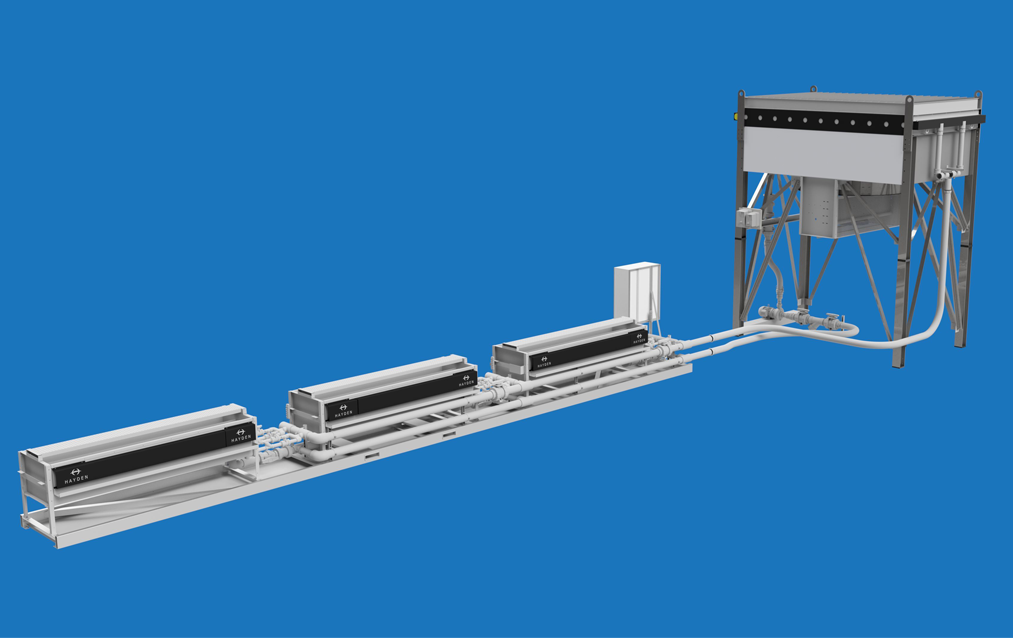

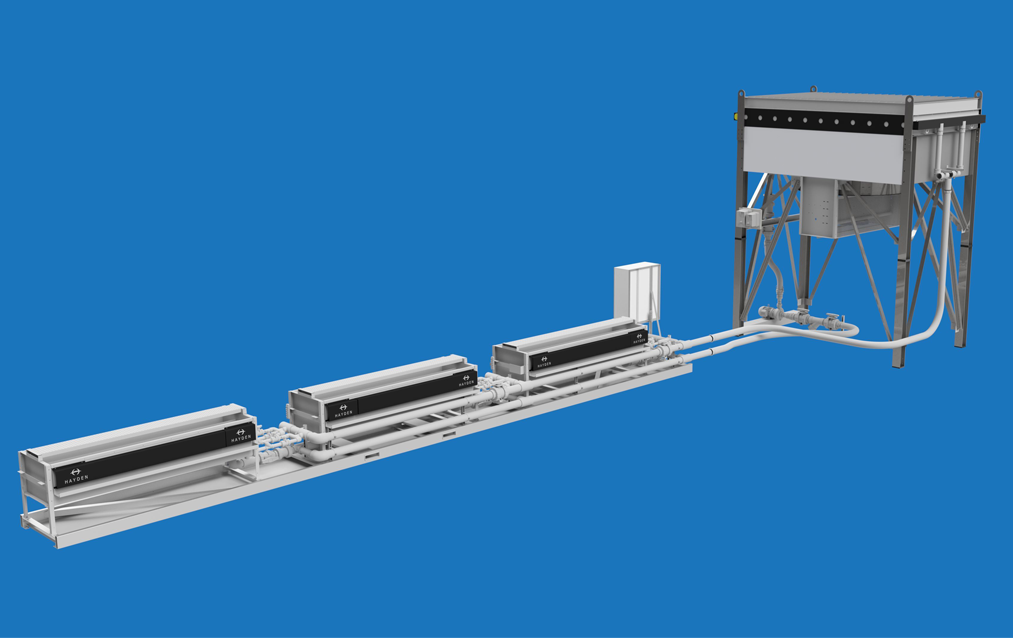

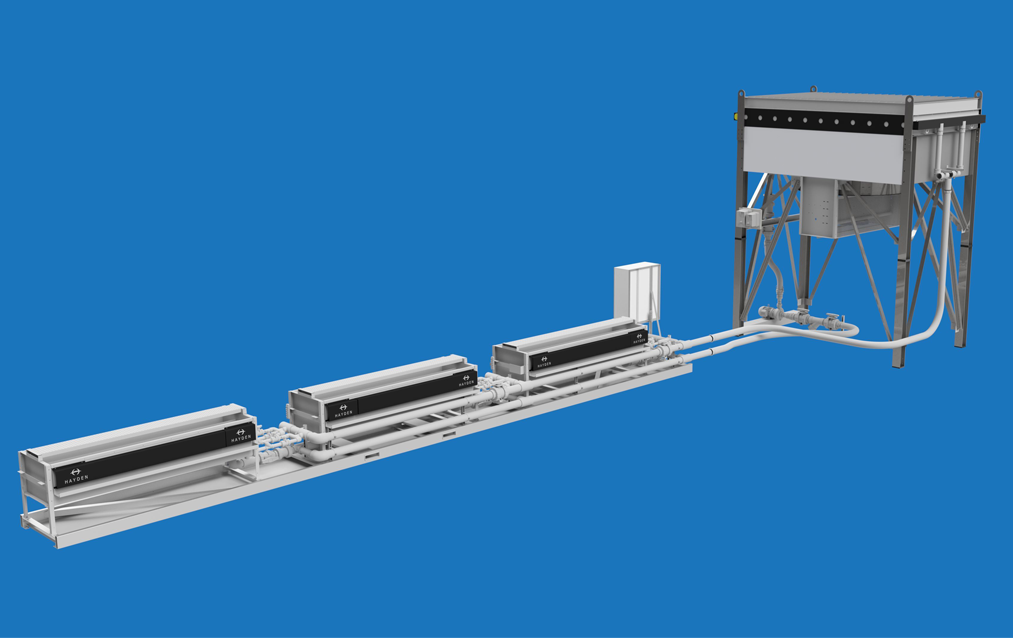

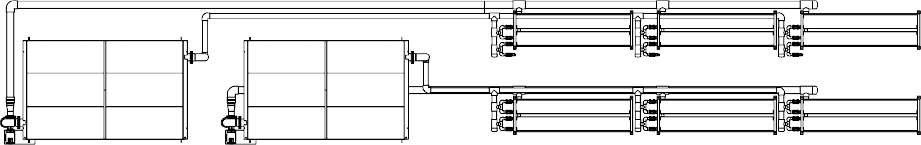

Hayden’s immersion skids make it simple to get facilities based mining operations up and running a quickly as possible. Simply fork the tank skids and heat exchangers into place, connect them with flexible hoses, and hook up power and network.

Our tank skids come with everything you need to mine except the miners. Our immersion software can easily scale to run 2 or 200 skids.

Technical Specifications

With 78 S19 series miners

Order now for delivery in 8 weeks

Each Skid Includes

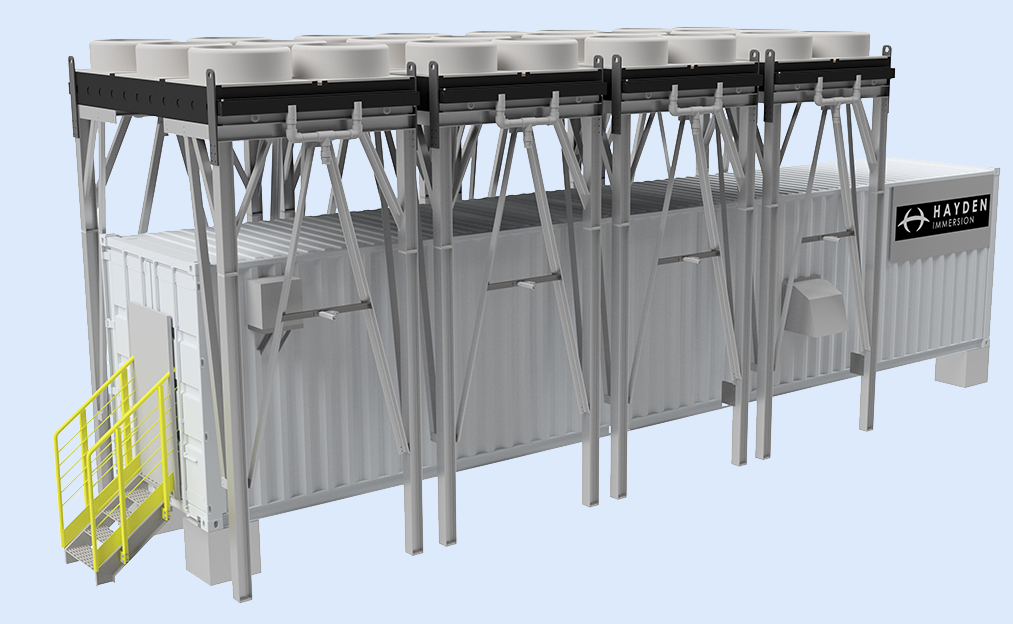

Ready to drop in place and only requiring hook up to power and network, and minor assembly, Haydens immersion containers are as close to plug and mine as it gets.

Our immersion container takes 4 of our incredibly effective tank skids and combines them in a 45' container along with everything else you might need to control, monitor, manage, and run 1.6MW of immersion mining.

Technical Specifications

With 312 S19 series miners

Order now for Q3 2023 delivery

Each Container Includes

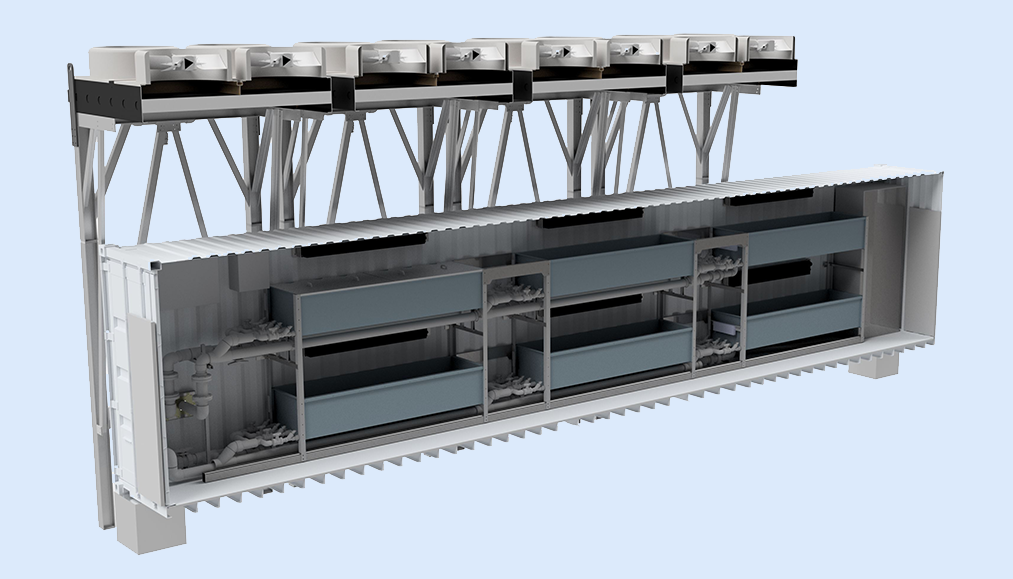

With two aisles for miners and an overflow in the center, every miner is easy to get at for maintenance

With PDU's integrated on each side of our tanks, customers have the shortest and simplest cable runs

Sliding from side-to-side, our drainage tray makes it easy to drain one miner, or half the miners in the tank at a time

Adjustable feet for leveling, grounding lugs, ethernet cable tray, switch mount, spill tray option...

You name it, we've thought of everything!

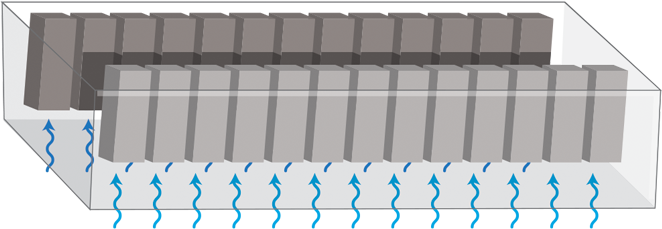

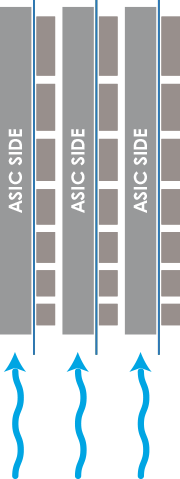

Our highly engineered fluid distribution system ensures that each miner gets an equal amount of flow, making our tanks incredibly balanced

We go further to direct much of the fluid to where the heat is – the ASIC chips – so flow isn't wasted on areas that don't need it

We’ve tested over 150 variations in tank design to come up with a system that functions at peak performance

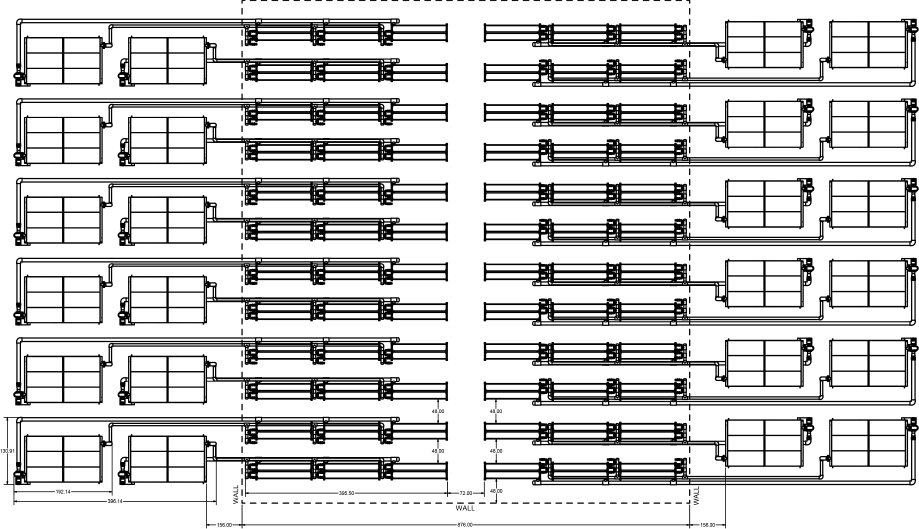

Hayden's yin-yang systems layout provides a high-density installation and an efficient use of space, while still allowing access to every side of every tank. Identical modular systems make for more cost-effective inventorying and procurement of replacement parts like pumps, seals, and fan motors.

The modular design easily scales to an entire facility and systems can be repurposed in different sized buildings, if necessary, or spread among multiple buildings.

Increase hashrate on miners up to 50% or reduce CAPEX to achieve a desired hashrate

Running on air takes its toll on miner hardware, with an expected 1.5-2 year life. Miners running in fluid can last indefinitely.

Facilities can be temperature-controlled when running immersion systems. Immersion tanks are virtually silent.

Heat exchangers produce 85dBa at 3 feet. Tanks are silent.

When miners run more reliability, fewer technicians are needed.

With our complete software solution, you can manage your plant from anywhere.

Hayden offers a line of aluminum braze air to oil (or water/glycol) heat exchangers designed and sized specifically for immersion blockchain mining applications. In the mining community, air to liquid heat exchangers such as these are often referred to as dry coolers.

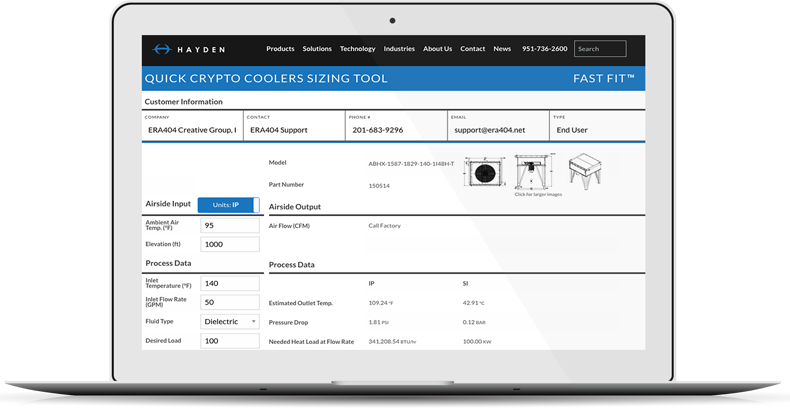

While lots of companies fabricate immersion cooling tanks for ASIC and other miners, very few have the capability for properly sizing the heat exchanger such that it will work at the exact environmental conditions any location can experience. Many solutions end up over, or more commonly, under sized.

We've designed, built, and tested our blockchain mining heat exchangers in immersion cooling systems with popular Bitcoin miners such as the Antminer S17 Pro and S19 Pro series and Whatsminer M31 series.

We offer 11 sizes ranging in capacity from 11 to 500 KW in a single core. Multiple cores can be combined for higher cooling capacities up to multiple megawatts. These heat exchangers can be sized to work with dielectric fluid (for single loop systems) or glycol (for dual loop systems).

Hayden has a Fast Fit™ sizing tool specifically designed for sizing heat exchangers for immersion cooling applications.

We offer bare cores, cores with fans and shrouds, as well as complete immersion cooling heat exchanger packages with included pumps and controls.

Hayden has been designing and building heat exchangers for over 60 years. We specialize in highly engineered solutions that meet specific customer needs, and provide solutions for just about any ambient temperature, from the Arctic to the Sahara Desert, in sizes ranging from small transmission coolers to very large lube oil cooler for gas turbines.

Our expertise in the highly engineered side of the heat exchanger markets, and as a supplier for dry coolers used in mining applications sees us uniquely positioned to provide a solution for the rest of the immersion system solution.

With our team of skilled mechanical, process, and software engineers, we’ve built arguably the best immersion system in the industry. We’ve run over 150 tank design variations through our immersion mining test lab to come up with a flow control system so good, you can run a tank within a few degrees of shutdown temperatures while still hashing.

Hayden operates out of our facilities in San Bernardino, California, Wuxi, China, and our newest and largest facility yet in Tulsa, Oklahoma, where we are building a newer and larger dedicated immersion test facility, and dedicated immersion system production facilities.